In metal spinning, the forming process is accomplished by the use of a spinning lathe. The lathe resembles a woodturning or pattern maker’s lathe but is typically of a sturdier construction.

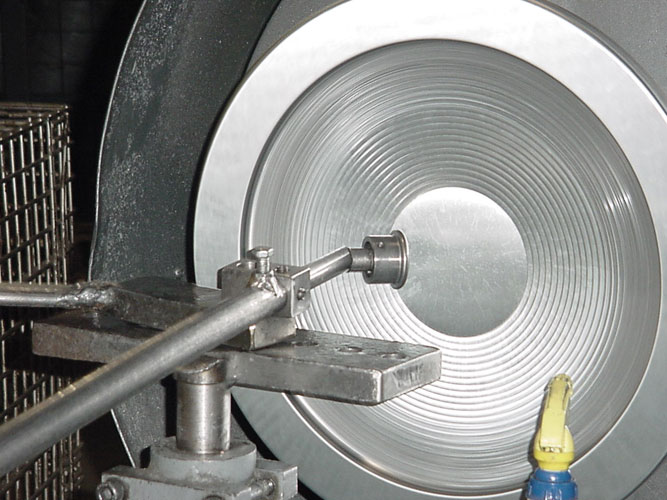

The material to be spun is first circle sheared to the required diameter and is then transferred to the lathe. Mounted on the lathe spindle is a spin form or mandrel, which duplicates the inside contour of the part to be produced. On the tailstock end of the lathe, a live center is installed and a tail block or “follower” is attached to the center.

The circle of metal is then placed between the tail block and spin form and the tailstock is advanced to securely hold the circle against the spin form. At this point, the lathe is started and all components rotate simultaneously.

The spinning process is accomplished by the use of pressure against the rotating circle from a “spin tool” which may take the form of a roller mounted on a lever, a hand tool or a hydraulically powered roller (which allows the forming of thicker or less formable alloys).

Some of the most common questions are answered on our Frequently Asked Questions page.

© 2019 L&S Industries | All rights reserved. Website Powered by Heartland Hosting, LLC | L&S Ind